Did you know

What makes a quality bur?

A dental practioner will invariably experience the difference in grinding efficiency of a bur. However the longevity of a particular bur is a lot more difficult to determine, as they go through the normal reprocessing in the dental clinic.

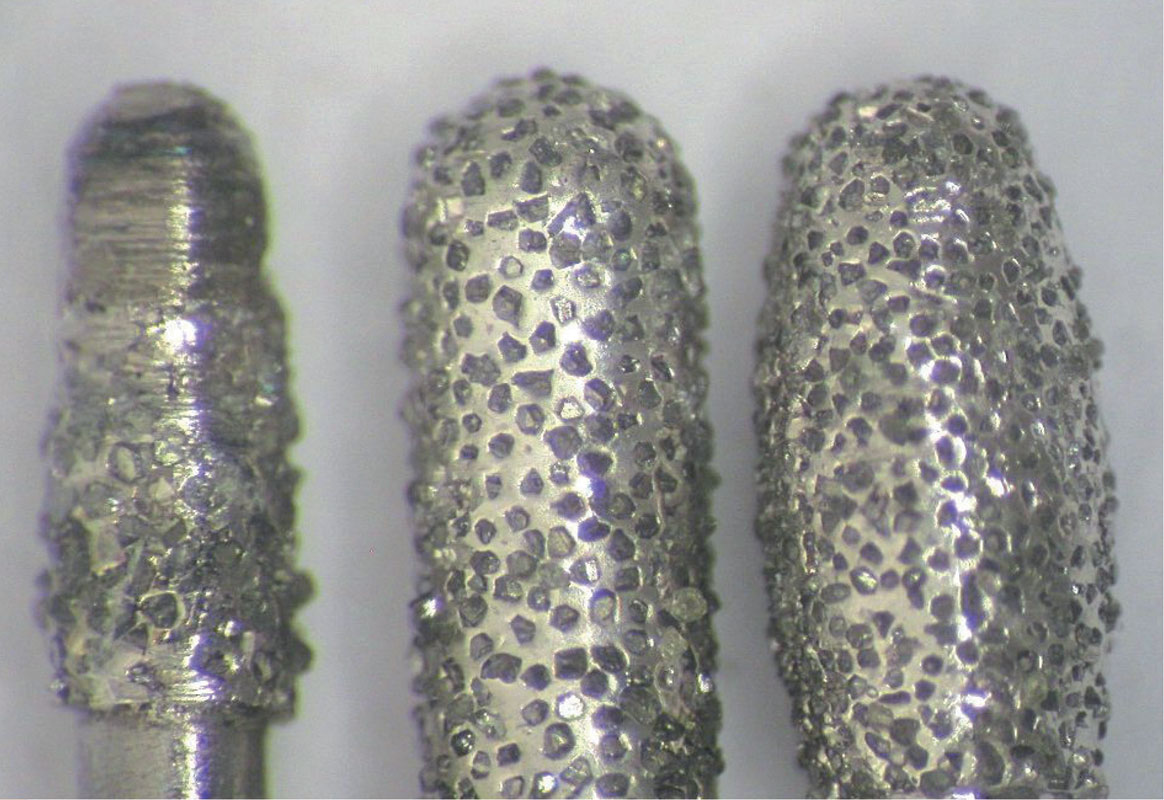

A high quality diamond bur, using traditonal galvanic bonding process, needs high bonding strength and optimal exposure of the diamond grits.

- A high bonding strength will naturally ensure longevity of the diamond bur

- Well exposed diamond grits will ensure efficient grinding

- Too much bond will not expose the diamond grits enough

In the manufacture of Viking diamond burs, the shank is pre-treated to increase bonding capacity with the diamond grit in preparation for the traditional galvanic bonding process.

Viking burs are inspected individually and several times during production as part of its stringent quality process, which is potentially much more difficult in larger automated operations.